Onllwyn Road Bridge

Onllywn, South Wales

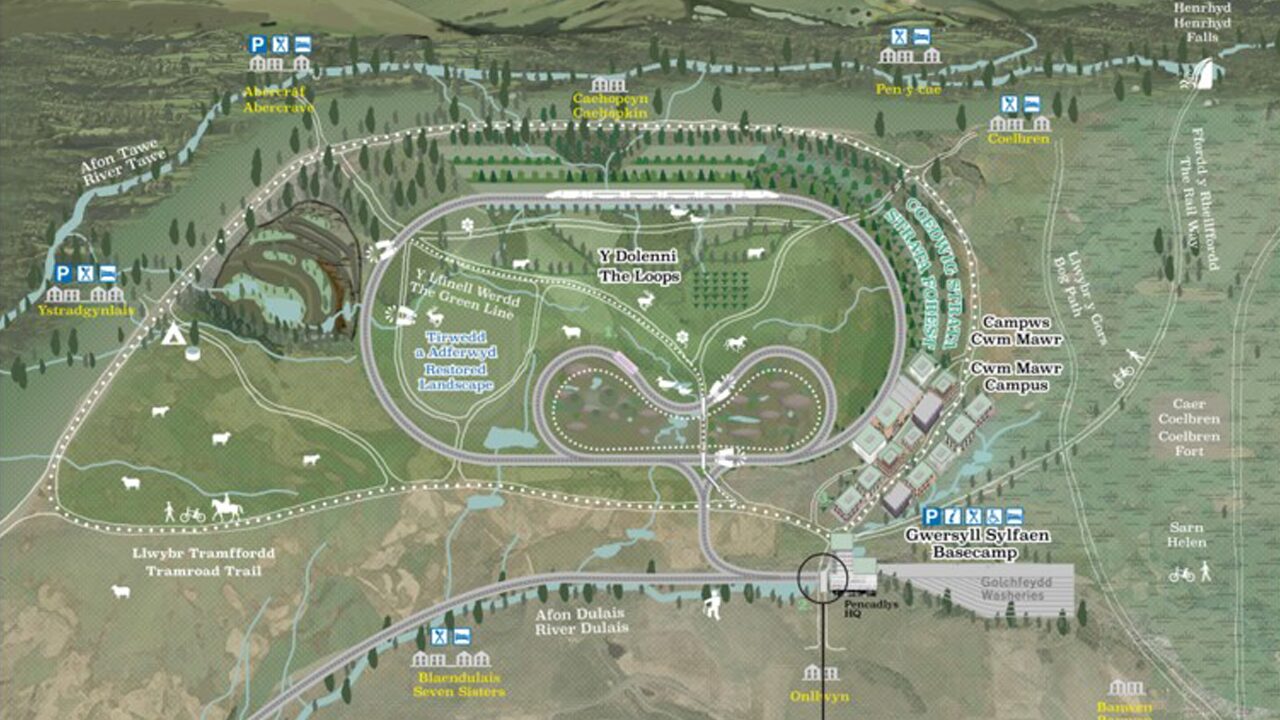

Expedition was commissioned to assess the possibility to reuse the existing 20m-span Onllwyn Road Bridge, located at the proposed Global Centre of Rail Excellence (GCRE) site in South Wales, and design a new one for cost and carbon efficiency. This project will be the first public facing component of the GCRE operations to be delivered and plays a significant role in setting the scene for the future development.

The GCRE is to be built at the head of the Dulais and Swansea Valleys, the site of the former Nant Helen opencast mine and Onllwyn coal washery. The scheme looks to convert the 700-ha opencast mining site into an innovation facility for world-class rail technology research, helping ‘create a more affordable rail network for tomorrow’. It will include two electrified test loops, one 6.9km-long high-speed rolling stock track and one infrastructure test track.

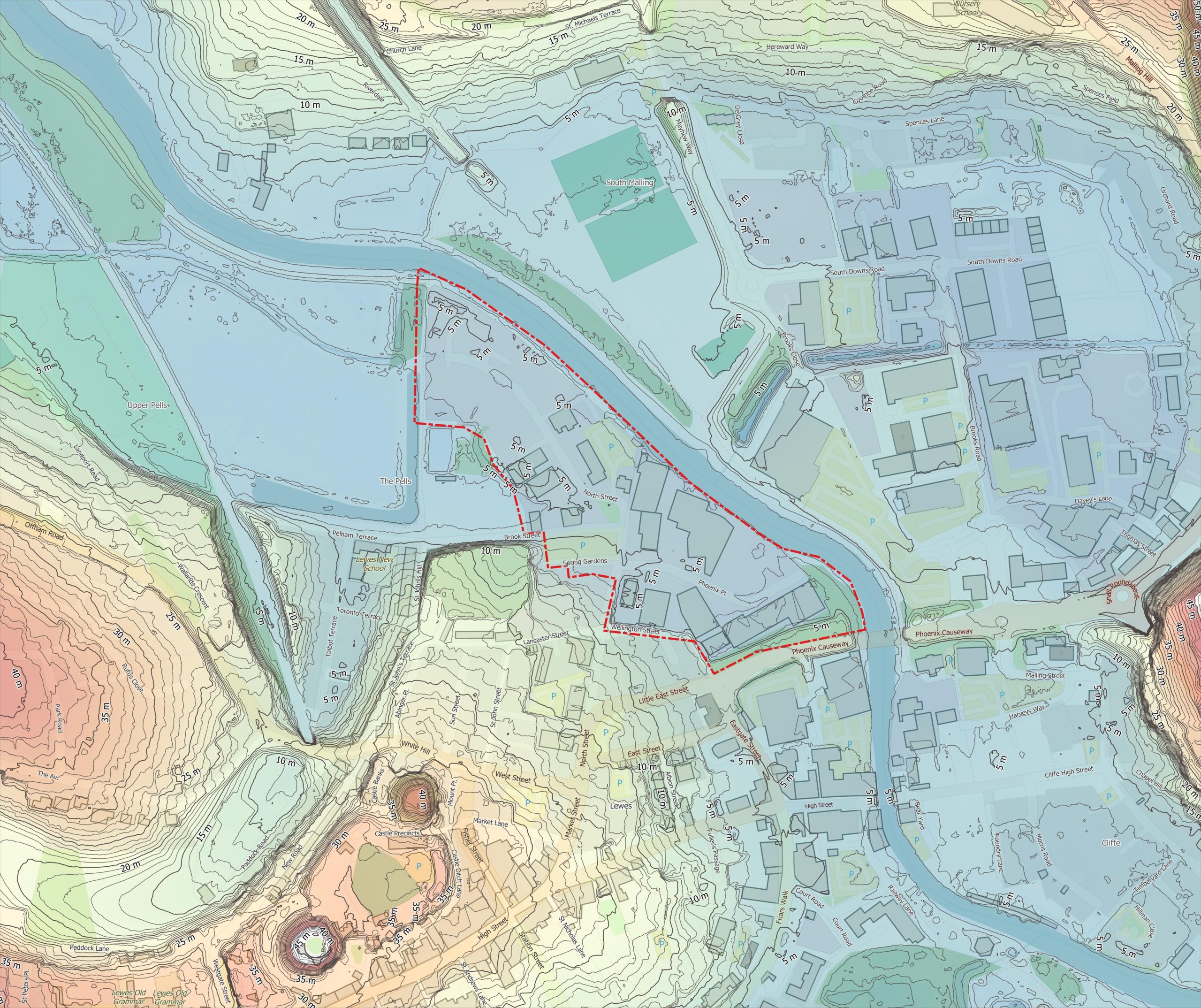

Built before 1945, Onllwyn Road Bridge carries a local road across the track to the existing Washery area. The existing structure is a typical steel riveted half-through bridge with a width of 3.8m, formed of two main I-girders and a deck that spans between them.

To allow modern trains to access the new electrified test loops, headroom on the bridge must be increased and our team established whether it could be strengthened or adapted to remain in place.

Powys County Council (PCC) and Neath Port Talbot County Borough Council (NPTCBC) were keen to add pedestrian and cycle access as part of a wider active travel network, but this was impossible in the bridge’s current form. Analysis revealed that as well as being too low, the structure was too narrow to be compliant with modern highway standards, even without this additional access. Our study confirmed that the most efficient way of addressing the structure’s physical constraints and futureproofing was to replace it, while making every effort to reuse the existing bridge as a pedestrian bridge elsewhere on site.

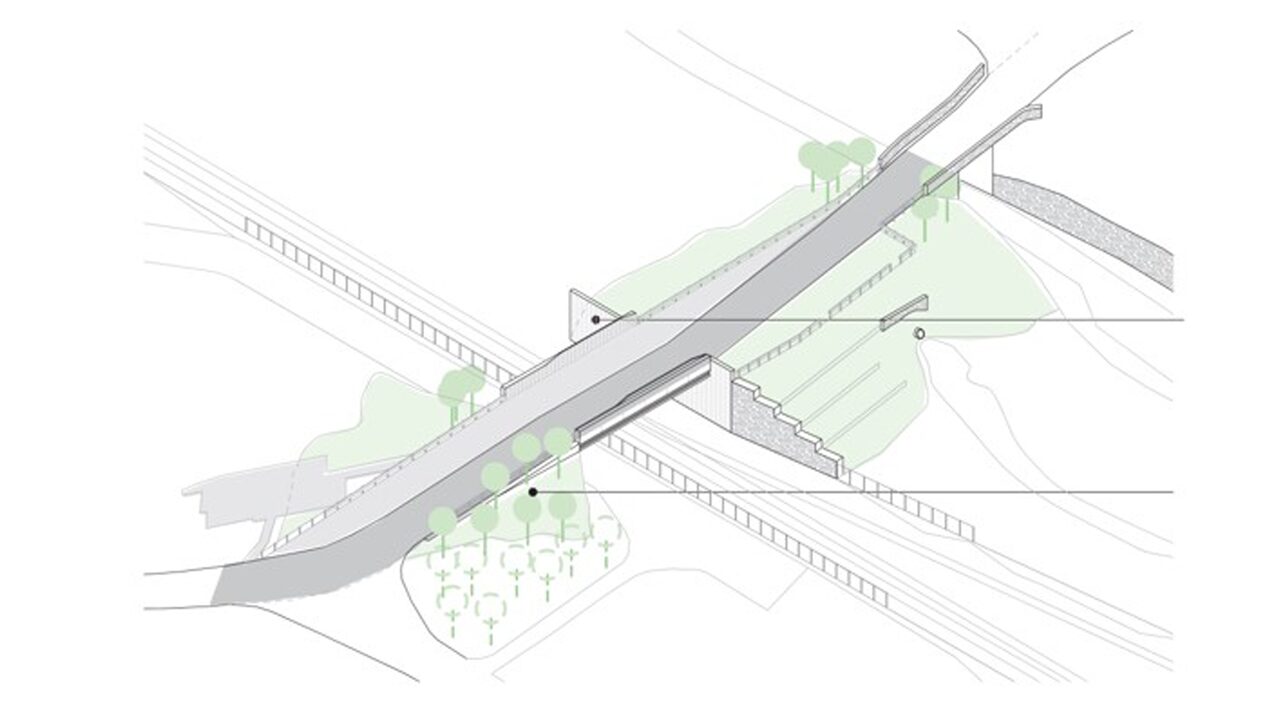

The council was also keen to minimise the bridge’s future maintenance burden, as any road closures have severe implications for local communities that rely on it. After a full options study, we chose low-carbon, cost-efficient precast concrete beams and designed an integral connection with the abutment wall to create a frame arrangement. The new bridge will be on the same alignment as the existing crossing, but at a higher level and with a slightly offset span and wider deck. The proposal combines a series of precast pre-tensioned concrete beams with an in-situ slab, cast on a thin precast slab acting as permanent formwork.

Expedition’s remit also extended to the civil engineering design, including earthworks and drainage design. We have prioritised the use of natural embankments and green slopes rather than retaining walls through the landscape design development, improving constructability, reducing cost, and minimising embodied carbon.

Our team considered the possibility that cavities from former mining activities may be present at the site. Although desk studies and liaison with the coal authority suggested they would be deep enough to have no impact, we took the precaution of designing shallow foundations and specified a probing campaign to locate precisely any cavity.