News

Expedition Engineering publishes groundbreaking study on reusing structural steel in bridges

Expedition Engineering, with funding from the Institution of Civil Engineers (ICE), is proud to announce the release of a pioneering report exploring the reuse of structural steel in bridge design and construction. Led by Project Director Clotilde Robin and Principal Researcher Hazel Needham, the study provides critical insights into overcoming key barriers to implementing circular economy principles in infrastructure projects.

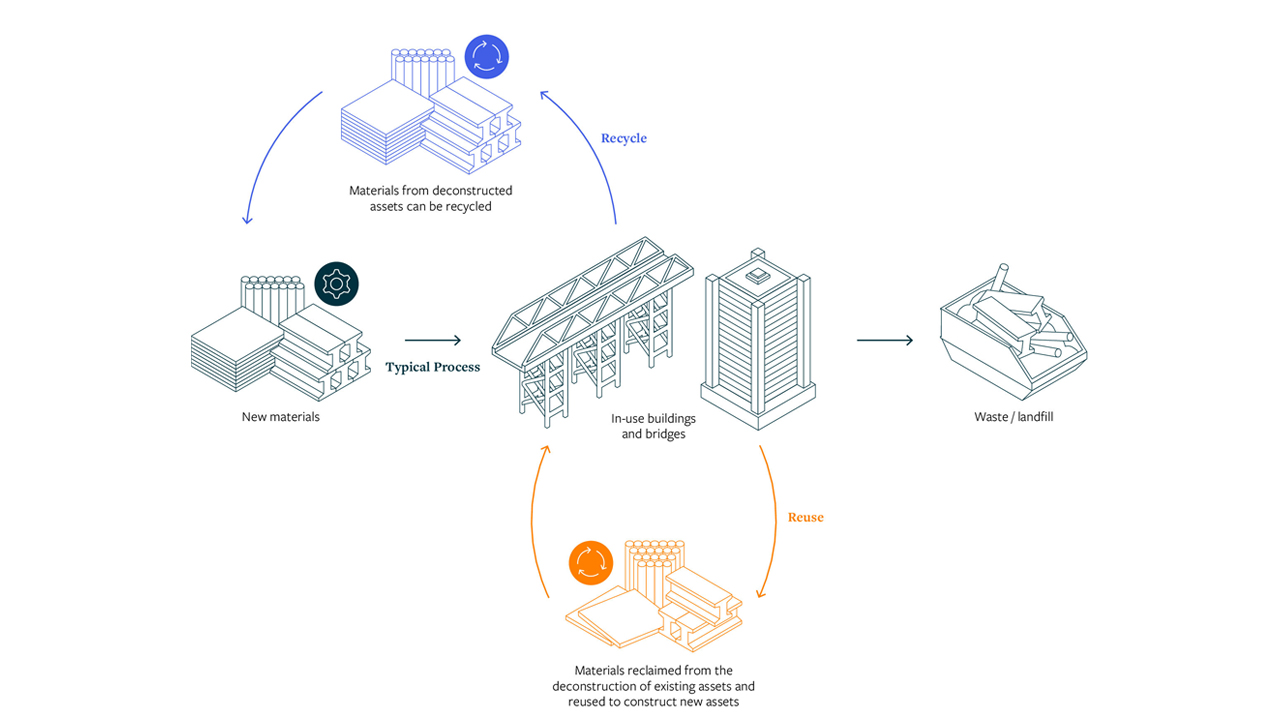

With the construction sector under increasing pressure to decarbonise, the report highlights how steel reuse offers a viable, cost-effective, and sustainable alternative to traditional recycling methods. However, regulatory constraints, procurement challenges, and risk management concerns have historically limited adoption. Expedition’s research addresses these issues directly, providing clear guidance on material qualification, certification, and design life considerations for repurposed steel in bridges.

The study underscores the importance of rigorous material testing to confirm the geometry, condition, and structural integrity of reused steel. A crucial factor in bridge applications is assessing fatigue life to determine long-term viability. Certification and compliance processes are expected to evolve, shifting toward a testing-based approach rather than reliance on CE or UK marking for individual components. While reused steel is generally more cost-effective than new steel, additional costs may arise from testing, reconditioning, and logistics – particularly when relocating entire bridge spans.

Despite these challenges, the supply chain for reusable steel is expanding, with sources such as Cleveland Steel playing an increasing role. The most successful reuse cases occur when clients own both the donor and recipient assets, streamlining logistical and commercial considerations. The study also emphasises the need for a resource-led, iterative approach to design and construction, requiring greater collaboration between designers, engineers, and contractors.

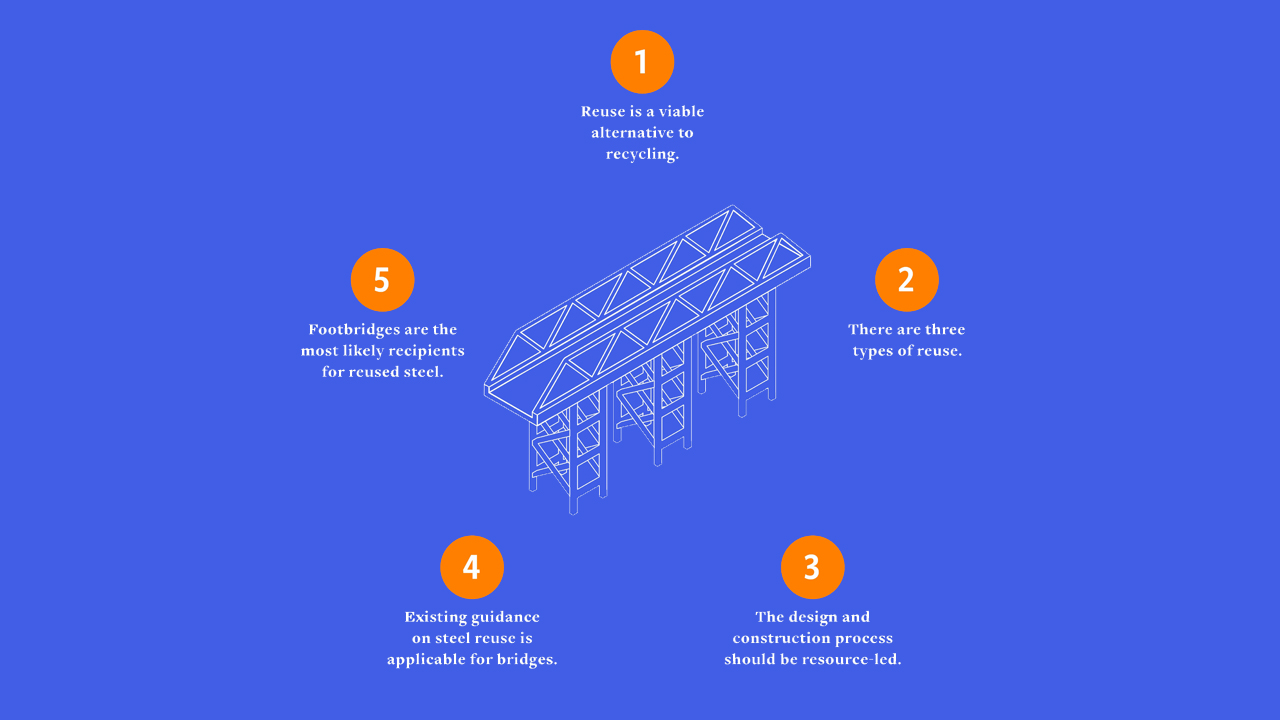

Three pathways to reuse

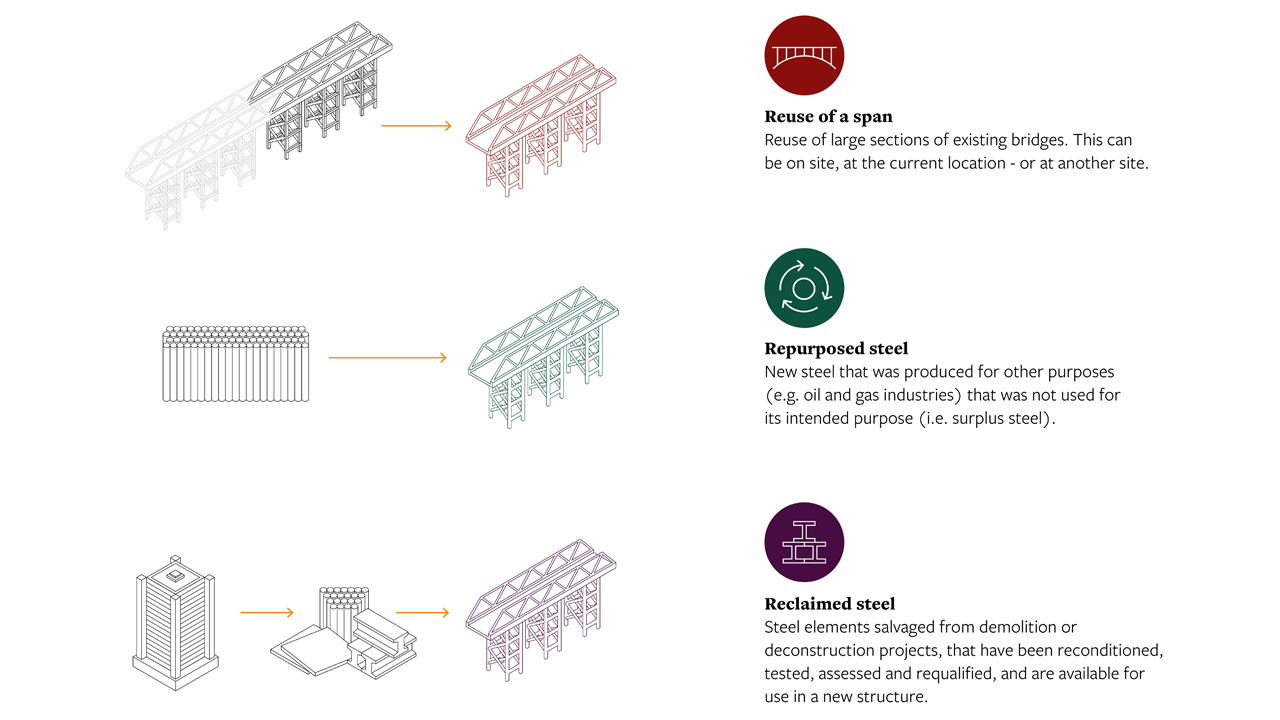

The Steel Reuse in Bridges report identifies three primary pathways for implementation:

- Whole-span relocation – repurposing entire bridge spans with necessary logistical adaptations.

- Repurposed steel – utilising surplus steel from other industries that require recertification.

- Reclaimed steel – extracting and reusing steel from existing structures after thorough assessment.

The report showcases a series of compelling case studies that bring the power of reuse to life.

Among bridge types, footbridges emerge as the most suitable candidates for reclaimed steel due to their lower fatigue sensitivity and the relative ease of implementation.

While advancements in ‘green steel’ production continue, the report stresses that reducing demand through reuse remains a crucial sustainability strategy. Simply recycling steel is no longer enough – proactive efforts to reuse existing materials with minimal post-processing will be essential in addressing the climate crisis.

Shaping the future of sustainable infrastructure

Expedition calls on civil engineers, policymakers, and construction professionals to embrace reuse as a fundamental design principle. The company remains committed to fostering industry-wide collaboration through direct consultations, industry roundtables, and event partnerships.

Read the Steel Reuse in Bridges report here.

-ENDS-