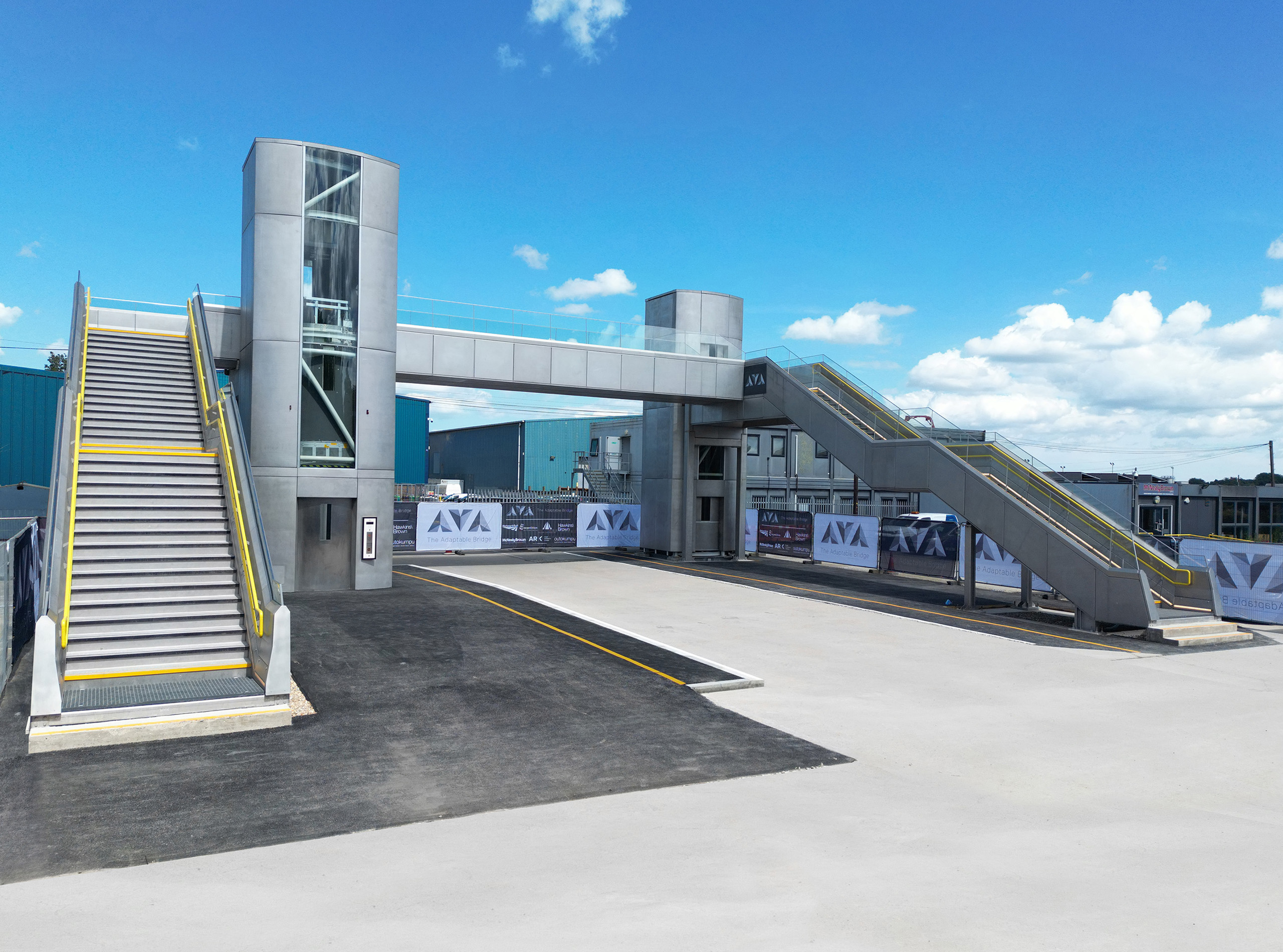

SBQ Teesside Freeport

Middlesbrough, UK

As GRAHAM’s innovation partner since 2021, Expedition is driving the implementation of the first phase of an ongoing programme of work and ambitious long-term collaboration through a Tiger Teams approach. With a focus on organisation-wide innovation and productivity improvement, this strategy is supporting GRAHAM’s live projects in unlocking savings opportunities, driving sustainability, and embedding a continuous improvement culture.

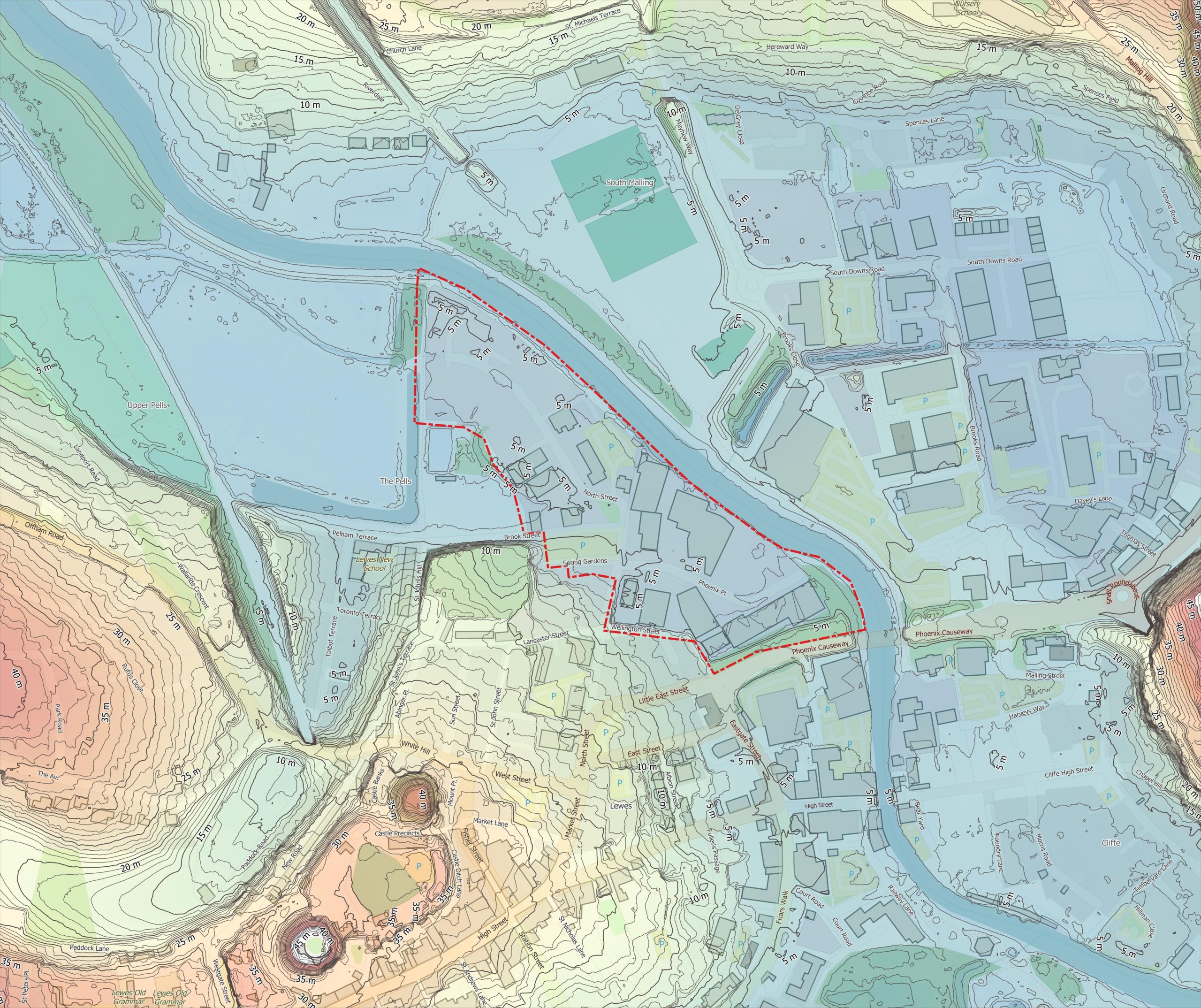

At the South Bank Quay platform, a major infrastructure asset for the Teesside Freeport, the Tiger Team unlocked a 51% productivity improvement rate for the installation of project-critical marine tie rods. Beyond the programme savings, our holistic multidisciplinary approach saw the reduction of exposure to H&S hazards by the equivalent of 31 working days per worker, reducing the site’s plant operating time by the equivalent of 18 working days.

The overall aim of this partnership is to harness innovation and cultural change in pursuit of lean construction, improved productivity, and positive impact on society. By analysing conventional procedures for common or repetitive tasks, we have identified how to make them simpler, quicker, and safer. We have worked with staff to introduce these changes and embed them across the company.

Our team of experts have widened the conventional definition of productivity to cover not just output, duration, and cost of work, but also workforce H&S and efficiency in plant use by implementing a structured framework to improvement. This approach focused on creating an integrated and collaborative team – including the design team, tie rods manufacturer and installation teams – to define a clear and measurable definition of the challenge. By aligning the objectives across the different stakeholders, we ensured that the project would lead to a common value creation. This holistic approach introduced H&S hazards/exposure and efficiency in the use of plant as fundamental criteria to assess productivity.

It was critical that a baseline for the activity was established to quantify gains and demonstrate benefits against. Time and motion studies and process mapping exercises were performed to identify the status quo and establish the baseline productivity. From this analysis, and collaboration within the Tiger Team, we identified ways to streamline the process and use the site operating plant more efficiently.

The final stage of the project focused on developing implementation plans for opportunities identified based on the agreed priorities and the impact they would have. The selected opportunities were implemented between July – August 2022, and a second round of time and motion studies were performed to measure the impact.

After this demonstration phase, the Tiger Team is focused in scaling up the approach and embedding change across the organisation and supply chain. This outcome-driven approach is currently being implemented in other projects dealing with complex engineering activities such as earthwork procedures.