AVA Footbridge and Lift System

UK

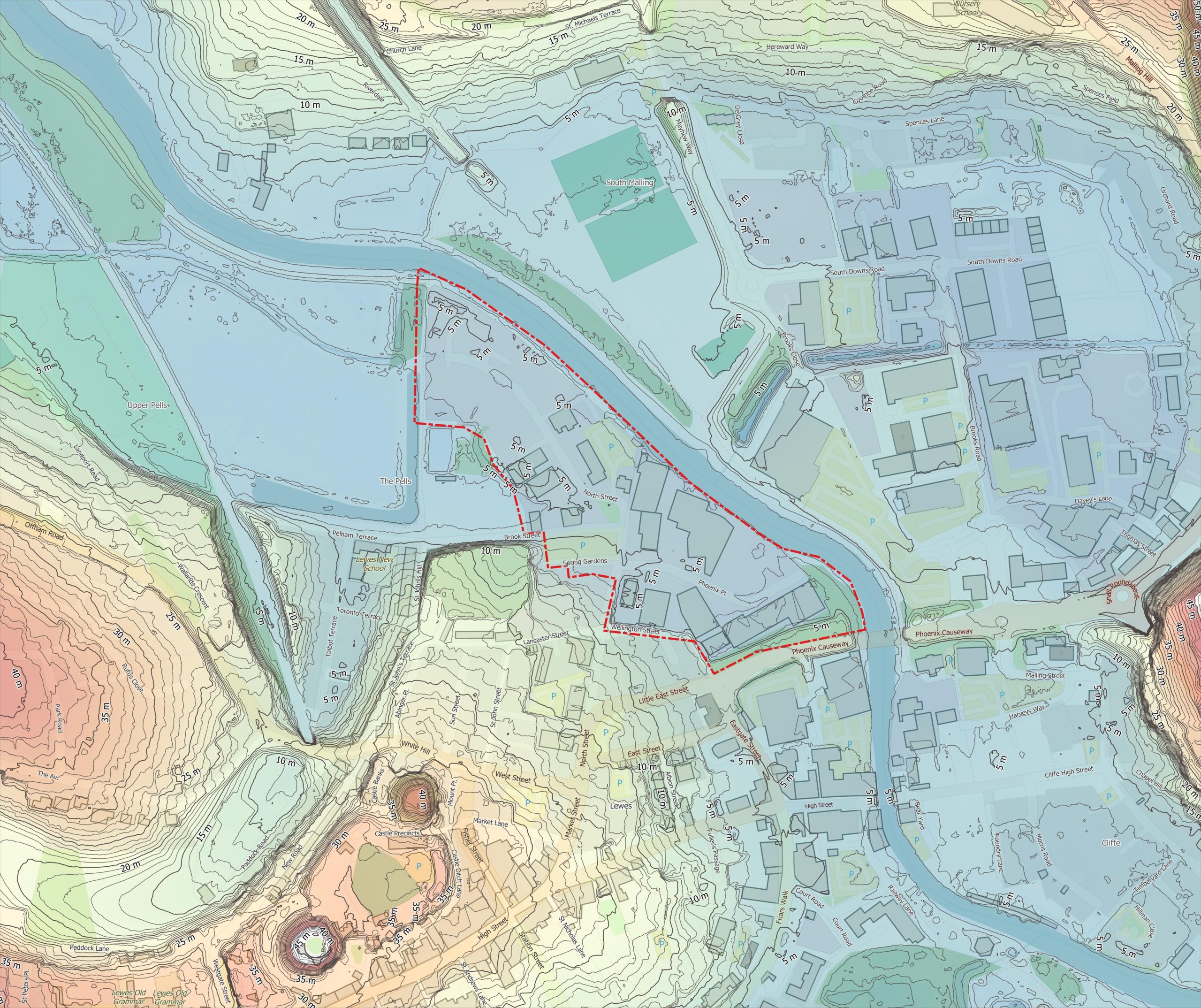

Aiming to make construction of railway footbridges quicker, cheaper and reducing their embodied carbon, we worked collaboratively in a Consortium to reshape the process, exploring ways to unblock the approvals bottleneck and exploit manufacturing benefits for savings. Expedition was lead designer to the group, assisting with creation of a full-scale demonstrator for installation over live railway tracks.

The future of footbridges

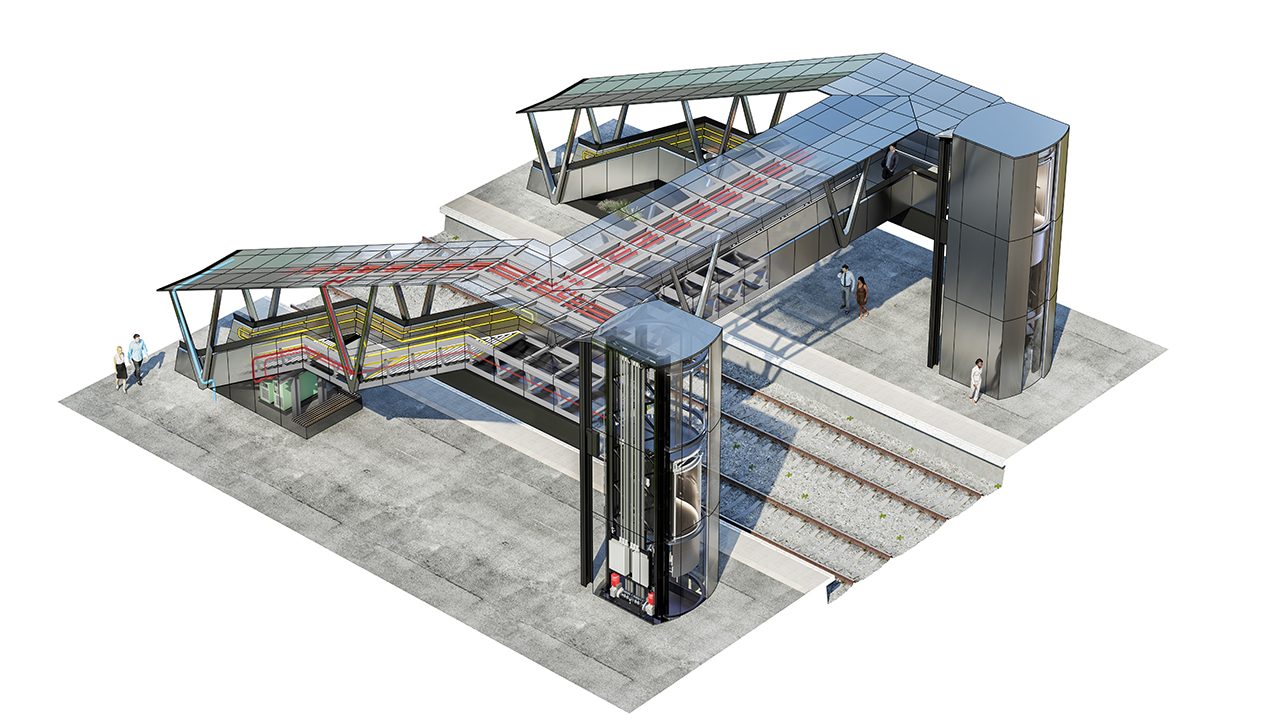

AVA marks a step-change in the way that railway footbridges are procured, manufactured and installed; a pre-approved system, created by a multi-disciplinary consortium of Expedition, Hawkins\Brown, Walker Construction and Xtreme Systems, it complies with all of Network Rail’s requirements, uses much less carbon, and can be rapidly installed with minimal time on site.

Its development stemmed from a recognition that the existing procedure was cumbersome, slow and inefficient, as well as being incompatible with Network Rail’s aspirations to reduce carbon and inhibiting rollout of its Access for All programme of work.

About one third of project costs are related to the design and delivery of footbridges – the remainder covers construction, indirect management, legal, risk, and other indirect process costs. The AVA consortium’s goal was to reduce or eliminate such cost and programme implications, and create a modular product that exploits the efficiency and reliability of modern manufacturing.

AVA Bridge was partly funded by Network Rail as well as being one of the TIES Living Lab demonstrator projects. TIES Living Lab is a collaboration of 25 partners together with government, i3P and the Construction Innovation Hub that use data, technology and modern methods of construction on live transport infrastructure projects to deliver value-adding benefits across the sector. The programme is funded via a grant from Innovate UK through the Transforming Construction programme, plus contributions from the Department for Transport, HS2, Transport for London, Network Rail and National Highways.

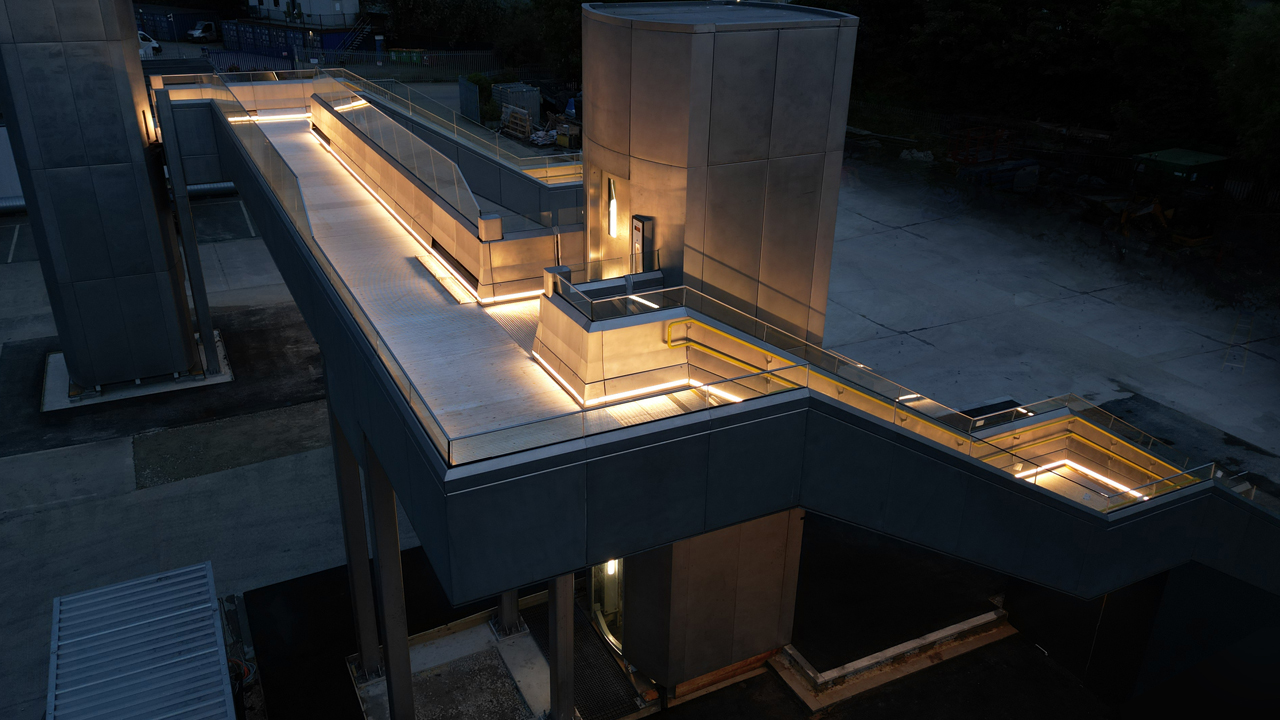

With ‘critical friend’ input from the Norman Foster Foundation, the project team came up with a modular system that can be configured to suit the location and the needs of the community. Each component and process was tested against the opportunity to save whole life carbon. The structure has a light, robust stainless steel structural frame and cladding system, which will be long lasting and require very little maintenance, significantly extending replacement cycles.

A new ‘plug and play’ glass lift was designed from scratch by SCX, and will be manufactured and assembled offsite, reducing the time needed to install and commission it.

The whole system is designed to shortcut the approvals processes and is optimised for manufacture, assembly, operation, maintenance, and carbon, significantly reducing the cost and programme compared with standard practice.

In the long-term, installation of an AVA bridge is expected to require just over a third of the time on site that it currently takes to build a standard footbridge. This not only has significant implications for reducing disruption to passengers and trains, but also for the safety of railway and site staff.

For AVA system enquiries, please contact Eva MacNamara.

Testimonial

Key People

"Hawkins\Brown has a great synergy with Expedition Engineers as they put people and society first. We worked together on the Innovate UK-funded AVA Bridge project, which saw us prototyping the next generation of low-carbon, pre-manufactured footbridges that can be rolled out anywhere on the network. We really benefitted from Eva’s excellent project leadership skills and naturally collaborative attitude, resulting in an exemplary project we are all very proud of."

Andrew Davies

Partner, Infrastructure Lead, Hawkins\Brown

Key People

Testimonial

"What makes this bridge so special? It's not just its eye-catching design or sturdy build, but its pioneering use of duplex stainless steels and modular construction methods. These innovations promise to transform how footbridges are procured, manufactured, and installed at railway stations. The AVA Bridge isn't just a structure; it's a testament to the future of sustainable, cost-effective engineering. With minimal maintenance needs and a stunning stainless steel finish, it's set to redefine the skyline of railway stations. Join us in applauding the AVA Team's vision and dedication to pushing the boundaries of bridge design."

British Stainless Steel Association