Chiswick Park Footbridge

London, UK

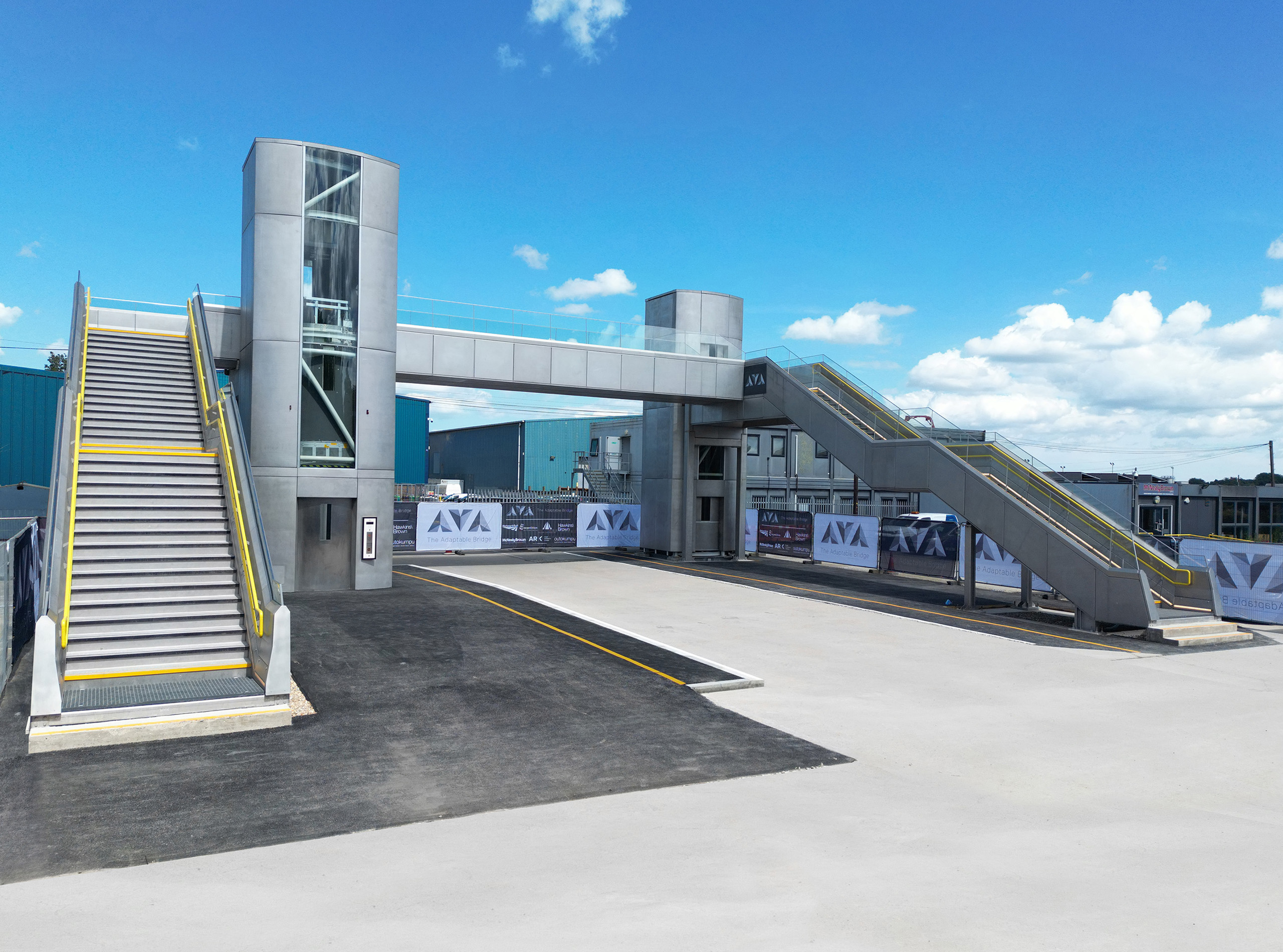

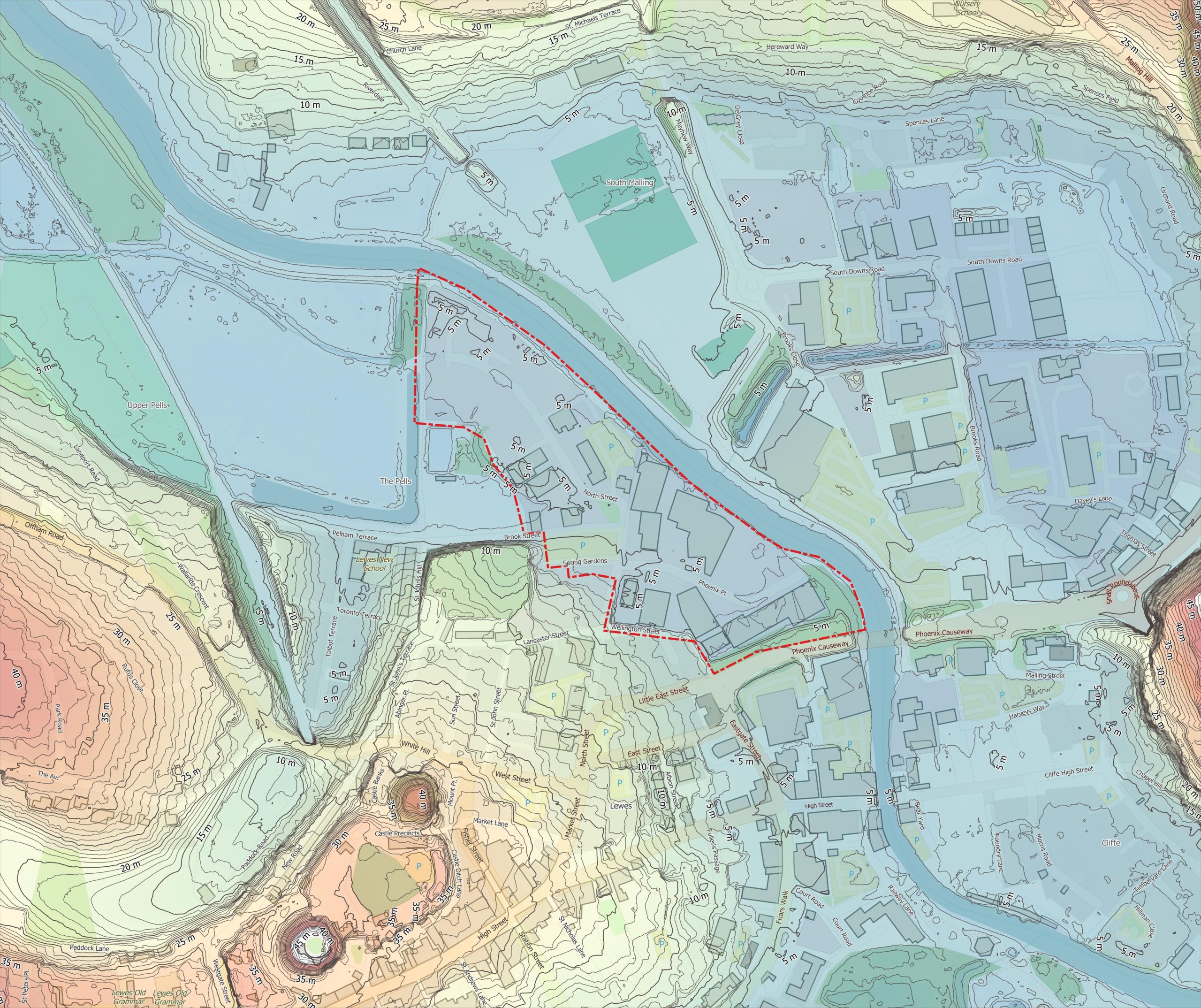

Designed for zero maintenance, this multi-span pedestrian bridge in west London sets a standard for the combination of form and function through collaborative design, delivering a striking landmark while reducing material use. Creative planning made construction simpler and quicker, minimising its impact on the operational business park and railway.

A key criteria for Expedition as Lead Designers in the development of this circa 150 m-long, three-span footbridge was to minimise future maintenance requirements. The project was a public-private collaboration between Chiswick Park owner Blackstone and the London Borough of Hounslow, with the local council responsible for its ongoing upkeep.

The structure provides a direct link from the business park to the closest tube station, previously only accessible by a circuitous route, by opening up a connection across the railway line that divides them; hence zero maintenance was also a major benefit for the railway spans.

We worked with our sister company Useful Studio to achieve this goal, by paring the design down to just three materials – weathering steel, hardwood timber and stainless steel – exploiting the structural form so that no dampers were necessary, and eliminating extraneous details where debris might gather.

The bridge has been made as simple as possible, and juxtaposes robust materials with the filigree nature of the network arch – a structural form that lends the necessary stiffness to long spans without undermining their slenderness.

The selection of a network arch was the logical engineering response to the challenge of creating a lightweight footbridge which did not vibrate excessively under the density of footfall it was designed to experience. The conventional solution of incorporating dampers in the structure did not suit the low-maintenance outcome we sought.

Construction was challenging due to its location on an operational business park, and installation over a railway line. We proposed and supported Lendlease to establish a DfMA procedure in which large-scale factory-fabricated elements up to 25 m long were brought to the site and assembled on temporary falsework into three full-length spans which were lifted into place over just two weekends.

Geometry can be a major challenge in the assembly of network arch structures, where shape is critical to resist buckling. To address this we developed an automated process for reviewing and signing off erection of the arch at key hold points, without delaying construction.

Testimonial

Key People

The mutual resolution of architectural form and innovative structural design conceals the complexity of the technical and geometrical constraints these bridges had to address. Brilliantly conceived, beautifully made and ingeniously erected, this project provides not only a much-needed physical link for the community, but also a remarkable local landmark.

Judges’ Comments

Structural Steel Design Awards 2019